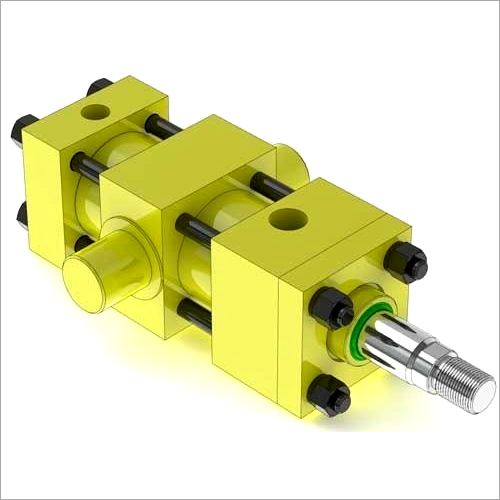

मà¥à¤à¥à¤¨à¥à¤à¤¿à¤ पà¥à¤à¤¿à¤¶à¤¨ सà¥à¤à¤¸à¤¿à¤à¤ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ सिलà¥à¤à¤¡à¤°

मà¥à¤à¥à¤¨à¥à¤à¤¿à¤ पà¥à¤à¤¿à¤¶à¤¨ सà¥à¤à¤¸à¤¿à¤à¤ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ सिलà¥à¤à¤¡à¤° Specification

- तापमान

- -20°C to +80°C

- दीवार की मोटाई

- 8 mm to 12 mm (depending on model)

- क्षमता

- Customizable as per application

- प्रेशर

- Up to 250 bar

- मटेरियल

- स्ट्रक्चर

- पावर

- आयाम

- Custom built (stroke and bore as per specification)

- मैक्स। स्ट्रोक

- Up to 2000 mm

- शाफ़्ट का व्यास

- 25 mm to 80 mm

- सील का प्रकार

- Polyurethane, nitrile, or VITON options

- रॉड

- Magnetic type, chrome-plated steel

- वज़न

- Varies as per stroke and bore size (approx. from 15 kg to 40 kg)

मà¥à¤à¥à¤¨à¥à¤à¤¿à¤ पà¥à¤à¤¿à¤¶à¤¨ सà¥à¤à¤¸à¤¿à¤à¤ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ सिलà¥à¤à¤¡à¤° Trade Information

- Minimum Order Quantity

- 01 टुकड़ा

- डिलीवरी का समय

- दिन

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About मà¥à¤à¥à¤¨à¥à¤à¤¿à¤ पà¥à¤à¤¿à¤¶à¤¨ सà¥à¤à¤¸à¤¿à¤à¤ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ सिलà¥à¤à¤¡à¤°

We bring forth a massive selection of Magnetic Hydraulic Cylinders in the market. These cylinders are suitable for complex machine tools and harsh environments of offshore drilling rigs & steel mills. These cylinders are easy to install and require minimum maintenance cost. These cylinders are strong, compact, and dimensionally accurate. We are prominent manufacturer and appreciated for our quality jacks and cylinders. These Magnetic Hydraulic Cylinders are made available in numerous bore sizes.

Features:

- Precisely designed

- Corrosion resistance

- Tough in construction

| Mounting Style | AS PER REQUIREMENT |

| Structure Type | Welded |

| Power | HYDRAULIC |

| Magnet Grade | N52 |

| Usage/Application | Industrial |

| Material | Iron |

| Max Pressure | 700 BAR |

| Brand | JYOTI HYDRAULIC |

| Size | TIE ROD |

| Bore Diameter | 350 mm |

| Cylinder Type | Double Acting |

Integrated Magnetic Position Sensing

This hydraulic cylinder incorporates a magnetic position sensor directly into its structure, enabling continuous and accurate feedback of the pistons position. Compatible with both analog and digital sensor outputs, it streamlines automation processes requiring real-time monitoring. The magnetic rod design ensures enhanced durability and precise motion control, benefitting applications that demand high accuracy and repeatability.

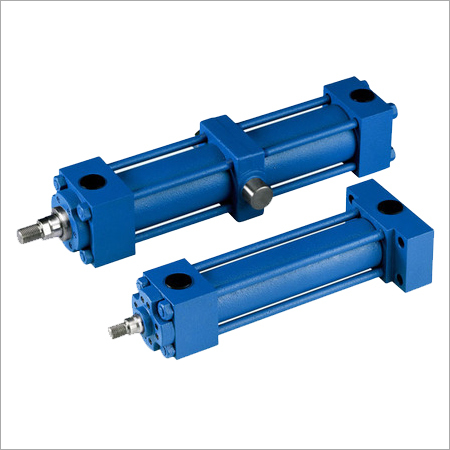

Corrosion-Resistant Construction

Engineered for longevity, the cylinder employs high-strength alloy steel with zinc or nickel plating and a polished finish, delivering robust corrosion resistance. The welded cylinder body and integrated magnetic sensor slot provide added structural integrity, making it suitable for harsh industrial environments. Its IP67-rated sensor housing offers reliable performance even in settings exposed to moisture or dust.

Customizable for Varied Applications

Available in a range of bore sizes, with stroke lengths up to 2000 mm and capacities tailored to specific operational needs, this cylinder is versatile and adaptable. Options for seals, cushioning, and mounting styles ensure compatibility with a broad spectrum of industrial automation, machinery, and material handling systems. The customizable design ensures optimal integration and operation within your setup.

FAQs of Magnetic Position Sensing Hydraulic Cylinder:

Q: How does the magnetic position sensor in the hydraulic cylinder work?

A: The cylinder integrates a magnetic position sensor within the piston rod, which detects the magnetic fields position as the rod moves. This allows for real-time, continuous feedback of the pistons location, with output available in either analog or digital form to interface directly with control systems.Q: What are the main benefits of using this cylinder in industrial automation?

A: Key benefits include precise position monitoring (repeatability of 0.1 mm), robust corrosion resistance due to surface treatments, and the ability to customize dimensions and capacity for specific automation requirements. Its advanced sensing capabilities improve accuracy and process efficiency, reducing downtime and maintenance needs.Q: When should I opt for optional cushioning at end positions?

A: Optional cushioning is recommended when your application requires damping of piston movement at stroke ends to minimize impact, noise, and wear. This feature is particularly valuable in rapid or heavy-duty operations within material handling and automated machinery systems.Q: Where is this hydraulic cylinder best utilized?

A: This product is ideally suited for industrial automation, heavy machinery, and material handling sectors where precise position sensing, high reliability, and durability under varied environmental conditions are essential. It is designed for use with hydraulic oil as the operating medium.Q: What is the recommended process for installation and connector selection?

A: Installation should follow the selected mounting style (clevis, flange, trunnion, or threaded), and electrical connections utilize either an M12 or standard connector. Integration involves wiring the analog or digital sensor output directly to the automation system, ensuring proper ingress protection (IP67) is maintained for the sensor housing.Q: How do I ensure compatibility with my hydraulic system and automation controller?

A: Provide your specific bore and stroke requirements, choose the appropriate output (analog or digital), and specify preferred mounting and connector types. Check that your controller supports the selected sensor output type and that your hydraulic fluid matches ISO VG 46 or equivalent for optimal performance.Q: What maintenance is required for long-term operation?

A: Routine maintenance involves periodic inspection of hydraulic seals (polyurethane, nitrile, or VITON), checking for oil leaks, and ensuring connector integrity. The corrosion-resistant surface and IP67 sensor housing minimize maintenance frequency, but scheduled checks help guarantee longevity and consistent performance.

Price 6500 आईएनआर/ टुकड़ा

- Minimum Order Quantity

- Delivery Time

- Main Domestic Market

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Hydraulic Cylinders Category

डबल एक्टिंग हाइड्रोलिक सिलेंडर

माप की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 1

मटेरियल : ,

पावर : Hydraulic

मूल्य या मूल्य सीमा : आईएनआर

सील का प्रकार : Polyurethane/Nitrile Rubber/Viton (depending on temperature and application)

हाइड्रोलिक सिलिन्डर

माप की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 01

मटेरियल : ,

पावर : Hydraulic

मूल्य या मूल्य सीमा : आईएनआर

सील का प्रकार : Polyurethane / Nitrile Rubber Seals

हाइड्रोलिक सिलिन्डर

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 01

मटेरियल : ,

पावर : Hydraulic

मूल्य या मूल्य सीमा : आईएनआर

सील का प्रकार : Polyurethane and nitrile seals

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें