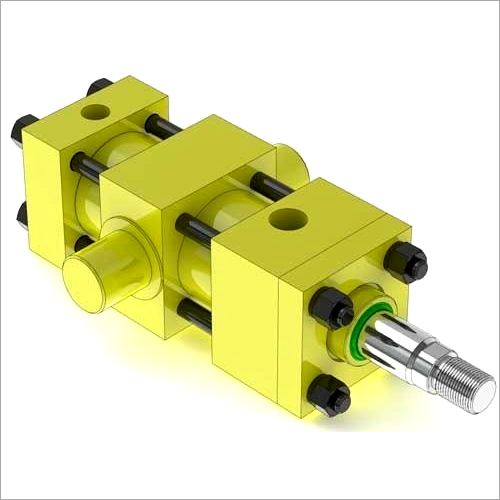

डबल à¤à¤à¥à¤à¤¿à¤à¤ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ सिलà¥à¤à¤¡à¤°

डबल à¤à¤à¥à¤à¤¿à¤à¤ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ सिलà¥à¤à¤¡à¤° Specification

- तापमान

- -20°C to +80°C (Standard)

- प्रेशर

- 160 - 300 Bar (Maximum operating pressure)

- क्षमता

- Customizable as per application

- दीवार की मोटाई

- 8 mm to 32 mm (Depending on bore size)

- मटेरियल

- स्ट्रक्चर

- पावर

- आयाम

- Bore: 40 mm to 200 mm, Stroke: up to 3000 mm (custom available)

- मैक्स। स्ट्रोक

- Up to 3000 mm

- शाफ़्ट का व्यास

- 25 mm to 140 mm

- सील का प्रकार

- Polyurethane/Nitrile Rubber/Viton (depending on temperature and application)

- रॉड

- Hard Chrome Plated Steel

- वज़न

- 18 - 250 kg (varies by model and stroke)

- Mounting Type

- Clevis, Trunnion, Flange, or Custom

- Return Type

- Double Acting

- Piston Rod Hardness

- HRC 50-60

- Finish

- Corrosion Resistant Paint

- End Connections

- Threaded/Flanged

- Surface Coating

- Chrome Plating

- Bore Size

- 40 mm to 500 mm

- Working Medium

- Hydraulic Oil

डबल à¤à¤à¥à¤à¤¿à¤à¤ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ सिलà¥à¤à¤¡à¤° Trade Information

- Minimum Order Quantity

- 1 Unit

- डिलीवरी का समय

- दिन

- नमूना उपलब्ध

- Yes

- नमूना नीति

- हमारी नमूना नीति के बारे में जानकारी के लिए हमसे संपर्क करें

- मुख्य निर्यात बाजार

- एशिया

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About डबल à¤à¤à¥à¤à¤¿à¤à¤ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ सिलà¥à¤à¤¡à¤°

Since our inception in the market, we have been engaged in providing premium quality Sensor Hydraulic Cylinder. Our offered cylinder is used for lifting the different materials & goods in different industries. The provided products are made at our advance manufacturing set up using premium grade basic materials with the help of latest techniques. In order to meet the requirements of our valuable customers, these are available in different specifications & sizes. In addition to this, the provided Sensor Hydraulic Cylinder can be purchased by our customers at reasonable prices.

Product details

|

Weight |

10kg |

|

Tube Diameter |

32 mm to 600 mm |

|

Mounting Style |

as per customer |

|

Power |

100 kg to 600 Ton |

|

Color |

as per customer |

|

Capacity |

>1000 Ton |

|

Usage/Application |

Industrial |

|

Material |

Iron |

|

Max Pressure |

700 bar |

|

Brand |

Jyoti Hydraulic |

Versatile Mounting Options

Designed for flexibility, our cylinders can be installed with clevis, trunnion, flange, or custom mounting to seamlessly integrate into your machinery. No matter your equipment layout, a secure and efficient hydraulic power solution is within reach.

Engineered for Longevity

Protected with corrosion-resistant paint and incorporating a hard chrome-plated piston rod, these cylinders resist wear and extend service life, even in challenging environments. The use of high-quality materials ensures consistent and dependable performance day after day.

FAQs of Double Acting Hydraulic Cylinder:

Q: How do I select the appropriate mounting type for my application?

A: Select the mounting typeclevis, trunnion, flange, or custombased on the specific alignment and force requirements of your machinery. Each offers different benefits, such as easy installation or enhanced support, to suit various operational needs.Q: What is the process for customizing a double acting hydraulic cylinder?

A: Customization begins with specifying your necessary bore size, stroke length, mounting type, and end connections. Our engineering team then designs the cylinder based on these parameters, selecting suitable materials, seals, and finishes to match your applications technical and environmental demands.Q: Where should double acting hydraulic cylinders be used?

A: These cylinders are ideal for applications requiring reciprocating force, such as in presses, heavy machinery, and automated systems across industries like construction, manufacturing, and material handling.Q: What are the advantages of a double acting design over single acting cylinders?

A: Double acting cylinders provide force during both extension and retraction, offering greater control and versatility in operations. This design improves efficiency for applications needing precise bidirectional movement.Q: How does corrosion-resistant paint and chrome plating improve cylinder longevity?

A: Corrosion-resistant paint shields the exterior against harsh conditions, while the hard chrome-plated rod minimizes wear and resists scoring. Both treatments significantly extend service life and reduce maintenance costs.Q: When should I choose Viton, polyurethane, or nitrile rubber seals?

A: Seal choice depends on the operating temperature and fluid compatibility; Viton is ideal for higher temperatures and aggressive fluids, while polyurethane and nitrile rubber are suitable for standard hydraulic oil in moderate conditions.Q: What are the benefits of using high-grade steel like EN8, EN19, or EN24 in hydraulic cylinders?

A: High-grade steels provide superior strength, reliability, and resistance to fatigue, making them ideal for high-pressure applications. This enhances operational safety and ensures longevity under demanding working environments.

- Minimum Order Quantity

- Delivery Time

- Main Domestic Market

- Main Export Market(s)

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Hydraulic Cylinders Category

हाइड्रोलिक सिलिन्डर

माप की इकाई : यूनिट/यूनिट

पावर : Hydraulic

मटेरियल : ,

न्यूनतम आदेश मात्रा : 01

मूल्य या मूल्य सीमा : आईएनआर

मैग्नेटिक पोजिशन सेंसिंग हाइड्रोलिक सिलेंडर

माप की इकाई : टुकड़ा/टुकड़े

पावर : Hydraulic

मटेरियल : ,

न्यूनतम आदेश मात्रा : 01

मूल्य या मूल्य सीमा : आईएनआर

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें