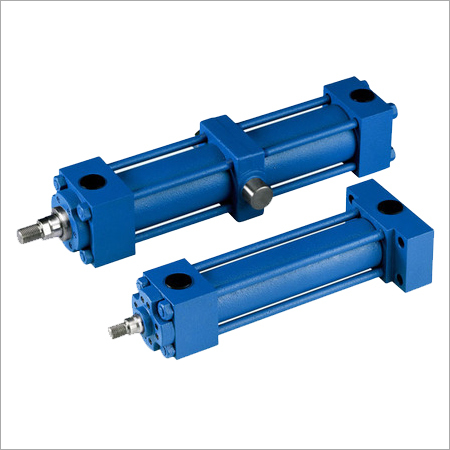

Sensor Mounted Hydraulic Cylinder

Sensor Mounted Hydraulic Cylinder Specification

- Capacity

- Customized As Per Requirement

- Temperature

- -10C to +80C Operating Range

- Pressure

- Up to 350 Bar

- Wall Thickness

- Standard: 8 mm To 25 mm

- Material

- High Grade Steel, EN8/EN9/SS

- Structure

- Double Acting Hydraulic Cylinder With Sensor Mounting

- Power

- Hydraulic

- Dimensions

- Varies By Model (Bore Size: 40 mm to 250 mm)

- Max. Stroke

- Up To 3000 mm

- Shaft Diameter

- 20 mm to 120 mm

- Seals Type

- Polyurethane/Nitrile Rubber

- Rod

- Chrome Plated High Tensile Steel

- Weight

- Depending On Cylinder Size (Range: 10 Kg to 120 Kg)

- Sensor Type

- Linear position sensor (magnetostrictive or reed switch compatible)

- Mounting Type

- Clevis, flange, trunnion, or custom mounting options

- Application

- Industrial automation, construction equipment, material handling, etc.

- Leakage Rate

- Nil (factory tested to rated pressure)

- Paint/Coating

- Corrosion-resistant epoxy paint

- Back-up Rings

- Available for high pressure applications

- Finish

- Precision ground and polished

- Operating Medium

- Mineral oil based hydraulic fluids

- Protection Grade

- IP65/IP67 sensor enclosures available

- Duty Cycle

- Suitable for continuous and heavy-duty applications

- Sensor Output

- Analog or digital feedback output

- Connection Ports

- Standard BSP/NPT or as specified

About Sensor Mounted Hydraulic Cylinder

Product details

| Tube Bore | 40mm to 300mm |

| Brand | Jyoti Hydraulic |

| Max Pressure | 700 kg/cm2 |

| Maximum Stroke | 8000mm |

| Rod Diameter | 16mm to 200 mm |

| Material | Stainless Steel |

| Capacity | >1000 Ton |

| Usage/Application | Industrial |

Versatile Mounting Configurations

Choose between clevis, flange, trunnion, or custom mounting options to precisely match your installation requirements. Our flexible design ensures compatibility with a range of machinery, enhancing integration in existing industrial setups without compromising stability or performance.

Advanced Sensing and Feedback

Equipped with integrated linear position sensors, the hydraulic cylinders offer real-time position tracking using analog or digital outputs. The compatibility with magnetostrictive and reed switch sensors provides reliable, precise data, ensuring greater automation and operational safety.

Durability and High Performance

Corrosion-resistant epoxy paint, chrome-plated high-tensile rods, and backup rings for high-pressure applications maximize cylinder lifespan. Factory-tested nil leakage at rated pressures and IP65/IP67 enclosures ensure these cylinders thrive under harsh or continuous-use environments, delivering performance and peace of mind.

FAQs of Sensor Mounted Hydraulic Cylinder:

Q: How do I select the appropriate mounting type for my hydraulic cylinder application?

A: Select the mounting configurationclevis, flange, trunnion, or custombased on your machinery or equipments space, movement, and load-bearing requirements. Each mounting style offers unique advantages for accommodating pivoting, fixed, or specialty mounting needs.Q: What are the advantages of integrating linear position sensors in hydraulic cylinders?

A: Linear position sensors provide real-time feedback (analog or digital), enabling precise monitoring and control in automated systems. This integration facilitates improved accuracy, operational efficiency, and system safety in industries such as construction, automation, and material handling.Q: When is it beneficial to specify corrosion-resistant coatings on hydraulic cylinders?

A: Corrosion-resistant epoxy paints should be specified when cylinders are exposed to harsh environments, including outdoor, marine, or chemically aggressive settings. This ensures extended service life and sustained performance by preventing rust and surface degradation.Q: Where can these sensor-mounted hydraulic cylinders be utilized?

A: These cylinders are ideal for use in industrial automation, construction equipment, and material handling systems due to their robust design, accurate feedback capabilities, and customizable features tailored to different application needs.Q: What process is followed for customizing sensor outputs and connection ports?

A: During order specification, choose between analog or digital sensor feedback and indicate standard BSP/NPT ports or other desired connectors. Our engineers will design and manufacture your cylinder to match these critical integration requirements.Q: How do backup rings benefit cylinders in high-pressure applications?

A: Backup rings enhance sealing effectiveness and prevent extrusion under high-pressure conditions (up to 350 Bar), safeguarding against leakage and extending cylinder lifespan during continuous or demanding operations.Q: What is the typical usage benefit of the IP65/IP67 protection grade for sensor enclosures?

A: IP65/IP67 sensor enclosures offer reliable protection against dust and water ingress, making these cylinders suitable for outdoor or wash-down applications and ensuring consistent sensor performance in challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Cylinders Category

Fork Type Hydraulic Cylinder

Price 8000.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Steel

Size : Standard Sizes

Usage : Industrial

Hydraulic Cylinder

Price 2000 INR / Piece

Minimum Order Quantity : 01 Piece

Material : Other, High tensile steel

Power : Hydraulic

Industrial Hydraulic Cylinder

Price 4000 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Steel

Size : Standard Sizes

Usage : Industrial

Power : Hydraulic

Hydraulic Compact Cylinder

Price 8000 INR

Minimum Order Quantity : 10 Pieces

Material : Steel

Size : Standard Sizes

Usage : Industrial

Power : Hydraulic

Send Inquiry

Send Inquiry Send SMS

Send SMS