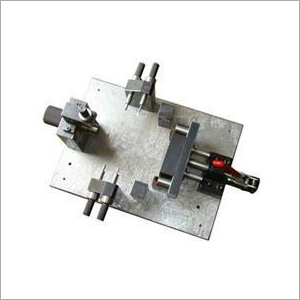

Jig and Fixture For Drilling

Jig and Fixture For Drilling Specification

- Working Process

- Precision Drilling / Hole Making

- Life Span

- Up to 3 Years (Depending on Usage)

- Shaping Mode

- Jig and Fixture Design

- Material

- High Grade Steel / Alloy Steel

- Application

- Drilling Operations in Manufacturing, Production, and Tool Rooms

- Hardness

- 58-62 HRC (Rockwell)

- Tolerance

- 0.01 mm

- Type

- Drill Jig and Fixture

- Customization

- Available on Request

- Corrosion Resistance

- Yes

- Operator Safety Features

- Provided

- Color

- Metallic Grey

- Production Capacity

- High Volume

- Mounting Type

- Bench Mounted

- Clamping Type

- Manual Clamping

- Surface Finish

- Polished

- Feature

- Interchangeable Bushings for Various Drill Sizes

- Weight

- Approx. 6-8 kg

Jig and Fixture For Drilling Trade Information

- Minimum Order Quantity

- 1 Number

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About Jig and Fixture For Drilling

With the help of our professionals, we are offering optimum quality Jig and Fixture For Drilling to our customers. This product is perfectly manufactured by using premium raw material and ultra modern procedures at our sound assembling unit. Under the strict supervision of our tenacious professionals, the offered product of drilling is altogether checked under few quality measures with a mean to make surrender free. Apart from all these, our clients can profit this Jig and Fixture For Drilling at market driving costs.

Product details

| Power source | Electric |

| Rated Voltage | DC 12V |

| Type | Drilling |

| Material | Stainless Steel |

| Usage/Application | Holding Workpiece |

| Hardness | 70 HRC |

Rugged, Efficient Precision for High-Volume Operations

Built for manufacturing environments, this drill jig and fixture streamlines production with exceptional accuracy and repeatability. Its high-grade steel construction assures durability, while the metallic grey polished finish resists corrosion, maintaining longevity even with rigorous use. The bench-mounted design and operator safety features enhance workplace efficiency and safety.

Versatility with Interchangeable Bushings

Adapt quickly to a range of drilling requirements using the interchangeable bushings that support multiple drill sizes. This flexibility reduces setup times, boosts productivity, and simplifies tooling adjustments during frequent size changes, making it suitable for diverse industrial applications.

Precision and Reliability with Every Use

Every fixture is designed to stringent 0.01 mm tolerances and 58-62 HRC hardness, ensuring consistent, high-precision results. Its manual clamping mechanism and robust build provide stable, secure operation, supporting high-volume production without compromising on quality.

FAQs of Jig and Fixture For Drilling:

Q: How does the manual clamping mechanism work on this drill jig and fixture?

A: The manual clamping system secures the workpiece firmly in place before drilling begins. Operators simply adjust and tighten the clamps to hold components stable during drilling, ensuring precision and reducing the risk of movement or errors.Q: What materials are used in manufacturing this drill jig and fixture?

A: This product is crafted from high-grade steel or alloy steel, delivering superior strength, hardness (58-62 HRC), and durability, essential for repeated use in demanding manufacturing and production environments.Q: Where can this drill jig and fixture be used?

A: It is utilized primarily in manufacturing plants, production workshops, and tool rooms where precision drilling or hole making is required. Its bench-mounted configuration makes it suitable for both large-scale and specialized applications.Q: When should I consider customizing the drill jig and fixture?

A: Customization is recommended when your production process involves unique workpiece shapes, specific tolerance requirements, or non-standard drill sizes. You can request custom designs to match your precise operational needs.Q: What operator safety features are provided with this fixture?

A: The fixture design includes dedicated operator safety features such as secure clamping, robust construction to withstand repetitive operations, and safeguards to minimize accidental contact, contributing to a safer working environment.Q: How do interchangeable bushings benefit my drilling process?

A: Interchangeable bushings allow you to quickly switch between different drill sizes, significantly reducing downtime during size changes. This flexibility supports varied drilling operations and enhances overall productivity.Q: What maintenance is required to ensure the optimal lifespan of the jig and fixture?

A: Regular cleaning, timely lubrication of moving parts, and routine inspection for wear will maintain the fixtures performance and extend its service life, which can last up to three years depending on usage conditions.

Price 12300 INR/ Number

- Minimum Order Quantity

- 1 Number

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Jig and Fixture Category

Jig And Fixture For Machining

Price 10000 INR / Number

Minimum Order Quantity : 1 Number

Shaping Mode : Other, Custom Shaped

Material : Other, Alloy Steel

Die Head : Not Included

Working Process : Other, CNC Machining

Rotary Joint Fixture

Price 3000 INR / Piece

Minimum Order Quantity : 01 Piece

Shaping Mode : Other, Precision engineered and assembled

Material : Other, Highgrade alloy steel

Die Head : Included, compatible with various rotary joints

Working Process : Other, Rotational machining, assembling, and disassembling rotary joints

Jig And Fixture For Machining

Minimum Order Quantity : 1 Piece

Shaping Mode : Compression Mould

Material : Steel

Send Inquiry

Send Inquiry Send SMS

Send SMS