मशà¥à¤¨à¤¿à¤à¤ à¤à¥ लिठà¤à¤¿à¤ à¤à¤à¤¡ फिà¤à¥à¤¸à¤à¤°

मशà¥à¤¨à¤¿à¤à¤ à¤à¥ लिठà¤à¤¿à¤ à¤à¤à¤¡ फिà¤à¥à¤¸à¤à¤° Specification

- डाई हेड

- Not Included

- काम करने की प्रक्रिया

- लाइफ स्पैन

- 5-7 Years

- शेपिंग मोड

- मटेरियल

- एप्लीकेशन

- Industrial Machining

- कठोरता

- HRC 55-60

- सहनशीलता

- ±0.01 mm

मशà¥à¤¨à¤¿à¤à¤ à¤à¥ लिठà¤à¤¿à¤ à¤à¤à¤¡ फिà¤à¥à¤¸à¤à¤° Trade Information

- Minimum Order Quantity

- 1 Number

- भुगतान की शर्तें

- कैश एडवांस (CA)

- डिलीवरी का समय

- दिन

- नमूना उपलब्ध

- Yes

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About मशà¥à¤¨à¤¿à¤à¤ à¤à¥ लिठà¤à¤¿à¤ à¤à¤à¤¡ फिà¤à¥à¤¸à¤à¤°

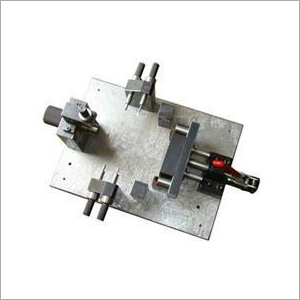

We are one of the famous manufacturers and supplier of Jig And Fixture For Machining for our valuable customers. It find its application in different industrial sectors to fulfill the demands of our customers. We make use of optimum quality material and latest machinery at our manufacturing unit for making these under the supervision of our professionals. It is therefore known for their long shelf life, strength, rust resistance, finishing and have a durability. Jig And Fixture For Machining is available in various sizes in order to fulfill the needs of our valuable customers.

Product details

Product details

| Surface Finish | Anodized |

| Tolerance can achieve | 0.005mm to 0.01mm |

| Material | Aluminium |

| Usage/Application | Holding Workpiece |

Built for Precision and Reliability

This jig and fixture is developed with high positioning accuracy in mind, utilizing precise locating pins and bushings. The robust construction supports up to 500 kg, making it suitable for heavy-duty industrial machining tasks. Accuracy and reliability are guaranteed for consistent results.

Custom Engineering for Every Application

We provide complete customization, including size, finish, and assembly features. Our design team leverages top-tier software like SolidWorks, AutoCAD, and CATIA to deliver jigs and fixtures that perfectly fit your machining processes and application requirements. Every unit is tailored for your workflow.

Cost-Effective Maintenance and Longevity

Thanks to its modular assembly, this fixture is easy to maintain and service. Corrosion-resistant finishes and premium material selection enhance its resilience, yielding a lifespan of 5-7 years. The versatile clamping types also streamline your operations, ensuring efficient and reliable performance over time.

FAQs of Jig And Fixture For Machining:

Q: How do I select the appropriate clamping type for my application?

A: You can choose from manual, pneumatic, or hydraulic clamping based on your operations requirements. Our team can advise on the best option considering your workflow, production volume, and precision needs.Q: What is the process for customizing the jig and fixture to specific dimensions?

A: Simply provide your required dimensions or technical drawings. Our engineers use advanced software (SolidWorks, AutoCAD, or CATIA) to develop a solution tailored to your specifications. Each fixture undergoes precise CNC machining for optimal fit and function.Q: When is it necessary to perform maintenance on the fixture?

A: Regular maintenance intervals depend on your usage rates and environment. However, the modular design allows for swift disassembly, enabling convenient cleaning, inspection, and part replacement as required to maintain performance.Q: Where are these jigs and fixtures manufactured and supplied from?

A: All jigs and fixtures are designed and manufactured in India, ensuring timely domestic supply and support, as well as international shipping for global clients.Q: What are the benefits of the ground and polished surface finish?

A: Ground and polished surfaces enhance corrosion resistance and provide a smooth, precise interface for workpieces. These finishes contribute significantly to the fixtures longevity and consistent accuracy.Q: How is positioning accuracy ensured?

A: High positioning accuracy is achieved using precision locating pins and bushings, maintaining tolerances within 0.01 mm. This ensures components are securely and accurately held during machining.

Price 10000 आईएनआर/ Number

- Minimum Order Quantity

- Delivery Time

- Main Domestic Market

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in Jig and Fixture Category

ड्रिलिंग के लिए जिग और फिक्सचर

माप की इकाई : नंबर

न्यूनतम आदेश मात्रा : 1

मटेरियल : ,

शेपिंग मोड : ,

काम करने की प्रक्रिया : ,

मूल्य की इकाई : नंबर

रोटरी जॉइंट फिक्सचर

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 01

मटेरियल : ,

शेपिंग मोड : ,

काम करने की प्रक्रिया : ,

मूल्य की इकाई : टुकड़ा/टुकड़े

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें